|

This colour really responds well to a good polish, nice work mate!

|

Good work there, amazing how much time can be spent on one part of the car isn't it. Very rewarding though when you look back at the 'before' pics

|

Great work with this Danny, looks slot different already to when it was collected.

Any more updates? Ps I still have the mirror caps from this, they are wrapped in carbon fibre, want me to peel it back and see if it's Mercury grey underneath? |

Quote:

If you could check the mirror caps out mate that would be awesome:y::y::y: |

Finally got the donor car stripped and disposed of. Can't believe how long its taken but I had to save every clip, grommet, fitting etc as I needed it all!

A general idea of how bare it ended up!(that sound deadening was the very last bit removed!)  Complete wiring loom removed without a single cut to any wire-I will need a lot of this as the previous track day warrior owner was snip happy with the loom!  I swear to god this must be the very first bit fitted when the cars were built new. Literally everything has to be removed the get this out the car in one piece!  Anyway, that then left me with far too many bits piled up in my garage so I needed to make a start on moving this little VTS forward. Had loads of holes in the floor to weld up where batteries etc had been bolted down.   Spent a whole morning splicing in new loom sections. Chopped wires everywhere!!! :(  All that was left of the stereo wiring!  Wiring for roof console re-attached and thread back through.(aerial as well)  Then after stripping what felt like everything from the dam thing, I got the bulkhead insulation back in along with the airbag ecu and wiring...  All floor sound deadening in..  I also seem to be at the stage now with these 106's/Saxo's where I seem to have quite a few of the same part! Picked the best carpet...  And to finish off for now, heater, blower and ducting all in along with the loom all clipped in to place.   Dash next, once my back, knees, neck etc recovers.... |

Any updates with this?

|

Quote:

Funnily enough I posted an update elsewhere today(bit quiet here really now )   Common issue on these little buggers. Nothing for it but to chop it out and repair it properly. If only Peugeot/Citroen had seam sealed them properly in the first place eh? Choppy choppy.    Then a bit of snip, trim, snip, trim, prime, weld, grind etc     Then onto another layer, gets rather boring but hey it's got to be done. At least I got to use a hammer for this one...    And to rap it up for now I ground the welds back and gave them a coat of etch.    There's a frilly bit left on this side but I'll worry about that next year when the suns out...  Best check the other side out now and see what that's like! If you want to see what I've been upto recently on it... http://autoshite.com/topic/22466-fre...t-hatch-shite/ |

Fantastic job of that welding Danny! Very nice to see the attention to detail adding the ribbing back in as it should be and not just slapping an 'it'll do/MOT passable' patch on like many do. It'll be the perfect repair when you get around to doing the last little bit that the arch liner fixes to.

Fancy doing some welding on my 309? ;-) |

Some very nice welding there, looking good mate!

|

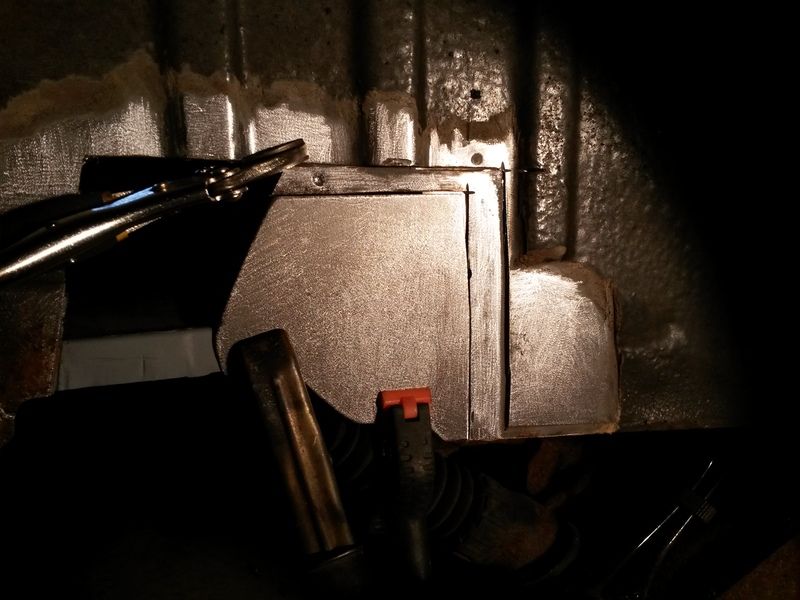

Managed to gain a couple of hours in the garage this afternoon so thought I had best take a look at the inner arch on the nearside.

Removing the arch liner revealed further crustiness.  It's always worth cleaning everything back before you start cutting to see just how far the rust has crept. It's amazing what lurks under seam sealer and stone chip.:wall:   Plenty to be on with on this side as you can see. Fortunately it's not rotted the whole way along so I think breaking it down in to 3 separate sections is going to be the best way forward. I've decided to start with the forward most rot first as it looks the worst and is a combination of 3 separate layers.  So cut out the first layer back to good metal to reveal the crusty second layer underneath.  Second layer cut out again to sound metal. Fortunately, the last layer is made of nice thick metal(it's a strengthener) so although slightly pitted from surface rust, it's cleaned up well.  Finished off tonight with a good coat of Bilt Hamber rust converter to remove any last traces of rust on the last layer.  Finish work on Tuesday for Christmas until the 4th January, so hoping to have both rear arches completely welded up by then.:y: |

You got cracking with that quickly since the pic earlier. Doesn't look too bad overall then. :-)

|

Quote:

I've also given all the fixings on the beam, heatshields and the brake lines a good blast with the penetrating fluid. Going to try and remember to repeat that exercise each time I go in there so that when it comes to stripping the beam, it might pull apart a bit easier...:boxing: |

great project coming up really clean

|

Very nice work on this I'm amazed how good you have made the patches look all other welding on the rear arches ive seen on saxos always looks a right bodge.

|

If I can weld a quarter as good as you one day I'll be amazed! Cracking work.

|

id be also looking under the front arches and under where ecu sits and also where fuse box is to make sure the metal is not rotted or gone soft very common problem just had mine both welded up. No harm in checking while you out n about with cutting n welding :)

|

Thanks for the comments guys:y: Really appreciate it.

I managed to get the o/s finished over Chtristmas. First off was the front section.        Then moved on to the rear and centre section of rot.   And finally with the majority of the welds knocked back. I'll finish them off when it's ready for stone chip and paint. Primer just protects it for now:y:  |

Awesome job on the welding and good luck with this. I've subscribed :y:

|

Would love to weld like this need to learn. Great job looking good.

|

| All times are GMT. The time now is 03:54. |

Powered by vBulletin® Version 3.8.2

Copyright ©2000 - 2025, Jelsoft Enterprises Ltd.