|

|

Quote:

I cant really see there being much more room for improvement from these engines mind. We are probably as close to the max figures we will ever see. |

Quote:

I'd imagine we are heading towards the maximum figure, but Sandys still striving for even better so you never know. There's about 5% between the RR figure and what the engines actualy capable of on the Engine dyno - I plan to open up the scuttle slightly to allow better air flow to the middle two cylinders and see if that helps :) |

Quote:

Its a shame that QEP and everything went to shit, as the dyno testing they were doing with Dave from Pumaspeed was proving very interesting. No scuttle FTW :D http://www.106rallyeforum.com/forum2...highlight=maxi - incase not read this, an interesting read on both his figures/the final production ones from oreca. |

Alot of the JRE engines I map on our engine dyno go to Steven Gault's rolling road once fitted in the cars over there. I know how the figures for those compare.

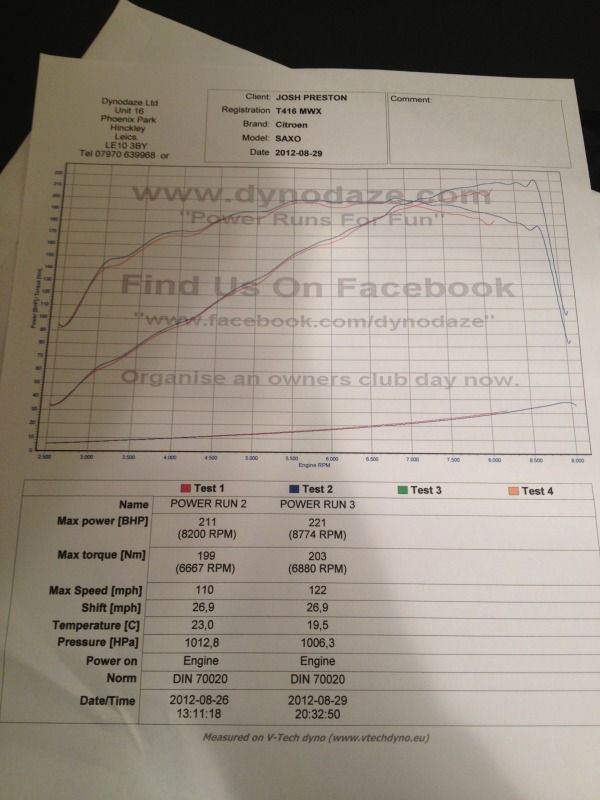

The last engine I dyno'd in this spec (engine dyno, DIN corrected and calibrated, not to be confused with the vagueness of rolling road figures), was almost identical to Josh's, the only significant differences were Jenvey SF bodies on my own manifold (same tract design effectively as Josh's) and the same geometry exhaust, made by a different fabricator. Peak figures were 234bhp at 8500rpm (as far as I tested it) and 159lbft at 6500rpm, with two slightly different inlet configurations. I tried alot of different injectors and injector positions, cam timing etc to arrive at this, two days of dyno testing on an engine I've already developed extensively. Here are the figures for two inlet tract variations I tried (these are the stable recorded steady state figures plotted on a simple Excel spread sheet):  Pictures of that engine on the dyno, showing some of the inlet/injectors variations I was testing:    Pics capturing the readout (DIN figures are what matter and ignore the Lambda display, we were using a separate one), believe me it was quite an emotional moment when I saw 230bhp+ for the first time!   Before everyone gets too carried away with peak or wide open throttle figures, I should point out the range of other qualities I have achieved with these engines that I'm proud of and I feel makes them stand apart from others... Driveability (they are totally road friendly and little need to be revved to perform), economy, no oil or water leaks even after a couple seasons, negligible breathing and oil consumption, so far total reliability and aside from the glitch with Josh's fuel system, after I've trimmed the map in the rollers and/or on the road once, that's it, they run sweetly until the next rebuild. I regularly dyno other people's race and rally engines of similar spec that customers have paid in the region of £13-15k for and don't perform anywhere near like this. I haven't got a set price for this spec, because individual builds always have a certain amount of variation, customers have an ECU already etc, but from scratch, with OE crank, exhaust manifold, ECU+loom, race clutch and steel flywheel, dyno'd and ready to use, it's about £11-12k. I do limit my builds, because of the other ongoing commitments I have (about half of my work is mapping, wiring and development for other engine builders; also the need to do scheduled work on existing engines) and currently the waiting list is well into next year so I'm afraid I can't really consider doing any more just now. |

Always wondered what sort of price these engines were. Cheap for a race engine though and in comparison to the work sandy puts into these engines to say pug1off which they use just some atpower itb's that are universal rather than custom to the engines spec along with things like the valves not being off the shelf and being machined to suit.

Can see why it takes months to build too, spends day and half just on a loom and I was very impressed my loom he made for me. |

Thamks for the write up sandy. As mentioned previously fully aware of some of the 'dark art' as such any information shared is fully appreciated by a large number of us on the forums.

I don't suppose you happen to have experience of the air boxes used in the rallye reg link? I've got one here but it's just the air box at the mo and no mounting system etc for me to see about putting it together. (I'll grab a pic when back on my mac)  |

I'm not really a fan of airboxes, they always have side effects and although they can lower the inlet temp in a static situation (ie queuing for a start or on a rolling road, out on the go, they really don't make much difference. I say that with quite alot of testing experience to draw on! My engines rely heavily on inlet and exhaust pulse tuning to do what they do and the air box design can profoundly affect that. Although I've seen airboxes produce spiked figure improvements on occasion, I've never yet seen one improve the delivery overall and single entry ones, like plenums, don't ever sound anything like as nice as open induction. On forward facing engines I like to have a nice wide open airbox where practical, that doesn't impact the pulse tuning; example, here's our 205 hilllclimb car, which we did as much to split and manage the ingested air to the rad, as to the induction:

|

Im not a fan of them either, but I cannot run on some tracks as it currently stands :(

|

That looks properly fun. What sort of league is that car in?

|

2 litre modified production hillclimb and sprint.

More about it here if you're interested: http://forum.205gtidrivers.com/index...owtopic=140057 |

That 205's a BEAST Sandy :D

|

I always love your write ups Sandy! :y: Top man for sharing so much info!

|

Ok time to properly update this from the start of 2012...where do I start?

So to begin with we stripped the car for Mark to do his work on it...   At Marks...  In progress...   Primered  And painted   And the underneath all repaired, stripped and painted/stone chipped    |

So then we began to build it back up... Satshifter & steering shiz first

Gearbox was rebuilt in the mean time, all bits were strengthened... (Thanks Tom!)   Carbon Lorraine RC5+ pads  Relocated both fuse boxes in behind the dash  Mark finished the CF Bonnet  & fitted the CF-look areocatches...   Fitted a proper SPAL fan  |

Now was time to fit the engine....

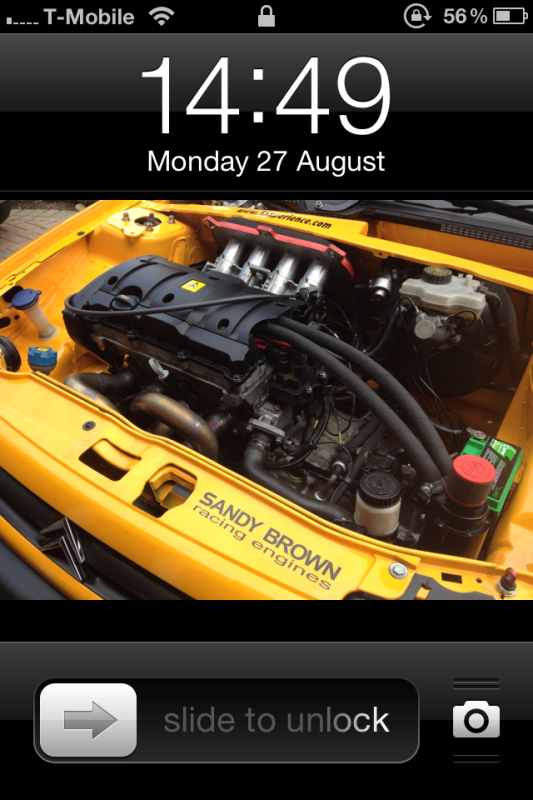

As most know; this is a Sandy Brown top 2012 spec producing silly power for a jp4 NA engine :D Sandy finished the engine in the back of his BMW lol  Put the engine in  Had a few issues along the way...  So out came the grinder lol  Oil cooler fitted  Modified the catch tank...    Fitted Sandys engine race loom   Dad made a bracket for the coilpack to sit neartly next to the engine...     Had a few issues with the clutch being too hardcore for the standard gearbox selector arm...  so that was beef'ed up by dad  and sprayed of course  Car was now ready, Olly then Trucked us down to 'Mike Edwards' for custom manifold / exhaust making & fitting to Sandy's spec      |

looking good matey, really do like how far you have gone with this especially as it started of as a normal westcoast! :D

|

From Mike's we towed it down to Sandys for lift off.... dad did an epic Leicester - London - Cornwall & back to Leicester trip in one day!

After a few issues we eventually got down to mapping the following day... The magician at work!  The engine was mapped as far as the standard pump could supply enough fuel... so I drove it back home to Leicester that evening and ordered a new intank fuel pump which was to be fitted as soon as it arrived...  In the mean time the manifold was turning nice funky colours :D  Mean while I set about adding a few lightening touches (battery weights 960grams!). My brother also made a DIY cage for the battery to hold it in place :)   Couple of ring stickers added (of course!)   Shift light carefully fitted & secured into the dash buttons  Tom Kindly offered to give it a good whoring :D   |

The fuel pump then arrived so we fitted that (what a bastard!)

Old one  New one  The problem (too big!)  I also tracked down the 2 remaining westcoast badges in the UK (one from up North & the other from Northern Island!)  Some Chimp (cheers Nick :D) also sent me my Mango citroen badge back.... lol  Couple of other bits in my obsession to make it as reliable as possible (old vs new)  |

The end result...

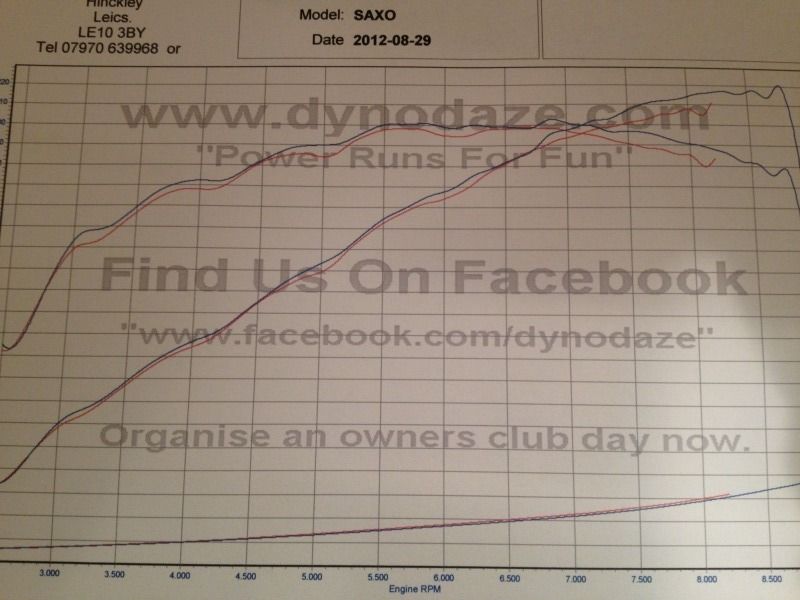

RED graph with old fuel pump BLUE graph with new fuel pump, you can see a clear improvement from 6,750rpm all the way to the limiter   |

TRAX 2012

Then it was time to have a bit of fun in it before I returned to the land down under to see the Sun :P   Best Saxo 2012 award :D   I also had a bit of fun out on track....     After Trax I popped over to Mallory with Lee to get it weighed... 805kg with half a tank of juice, just need to find another 5kg of weight saving now lol  Finally it was time to store it away for the winter while im in Sydney... gave it a lick of paint first (with the help of the mrs & my brother!)  And you can see it hiding behind my shitbox 106XR daily up on Axel stands with no steering wheel / ECU / Battery etc  I certainly wont be forgetting it while im away :D  |

| All times are GMT. The time now is 22:18. |

|

Powered by vBulletin® Version 3.8.2

Copyright ©2000 - 2025, Jelsoft Enterprises Ltd.