Strut Brace Time

I've been meaning to start this thread and start this brace but because it's been really busy at work I haven't had the chance to get stuck into it. But now I have ... I'm using 6mm thick 304 stainless steel plate. You dont need to use stainless steel or even as think as 6mm. I have seen other braces using 3mm thick plate.

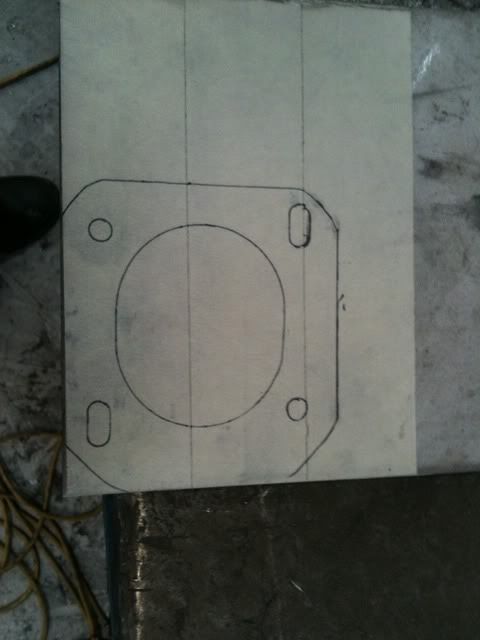

First Off

The shape and design of the pad ... All I can reveal it has been borrowed from a well known Italian steering wheel manufacturer (not Momo) ... thanks Steviee90, I will make a template once I have finished and upload it as a full sized image (downloadable) so others who want to use the pad design.

Cutting

Cutting

I used a grinder to cut out this piece nothing really too technical about this step so I won't go into it much. Just remember to use a sanding disc to smooth off all the edges...

Drilling

Drilling

The next step was drilling the two normal holes which were drilled at 8.5mm, the slotted holes are also 8.5mm but because I'm in the engineering industry I was able to put it into the punch (so much easier than drilling a few holes the using a small file to smooth off the holes)

Finishing Touches

Finishing Touches

Because I'm lucky enough to work in the industry I was able to use a plasma arc to cut out the hole for the top of the strut. If someone who doesn't work in industry is trying to do so I would advise using a 50mm metal holesaw to cut it out and try and bore the rest out using a rough file.

Forgive the rough looking holes as I haven't finished my ones but I felt I should get a crack on with making this strut brace. Make two of these and your golden ... thats you made the two pads for the brace

Next Step

Angled Flat Bar

The Flat Bar is 30mm at it's highest point and 10mm at the lowest, the full measurement is 135mm with two bent angles (which one again I will put in a downloadable content). It's basically 45,45,45 for each of the three sections.

Totally forgot about taking pictures so please forgive as I will add more pictures later as I have another set of angles.

How does it look ?

How does it look ?

Cross Pipe

Cross Pipe

As you can see I'm making it all in stainless steel, finally I have found some 3/4" stainless pipe.

As you can see I have finally started on the cross pipe part to span over the engine.

Sitting nice in the bay...

Hopefully be in the workshop soon so I can bend the angles ... not to sure if I will either use a hydraulic pipe bender or heat bend the pipe.

Well I've been having fun with blasting sand, Propane & oxygen burning nozzles...

Tomorrow i will be polishing the above pipe (will post a picture of it cleaned up when its been done), hopefully have it all complete for friday afternoon.

The angles aren't that far off they might just need some fine tuning.

Now this is finally finished and here is some bay pictures

Now this is finally finished and here is some bay pictures

If you want to check out the full set of pictures for the start to finish of this strut brace click

here.